Introduction

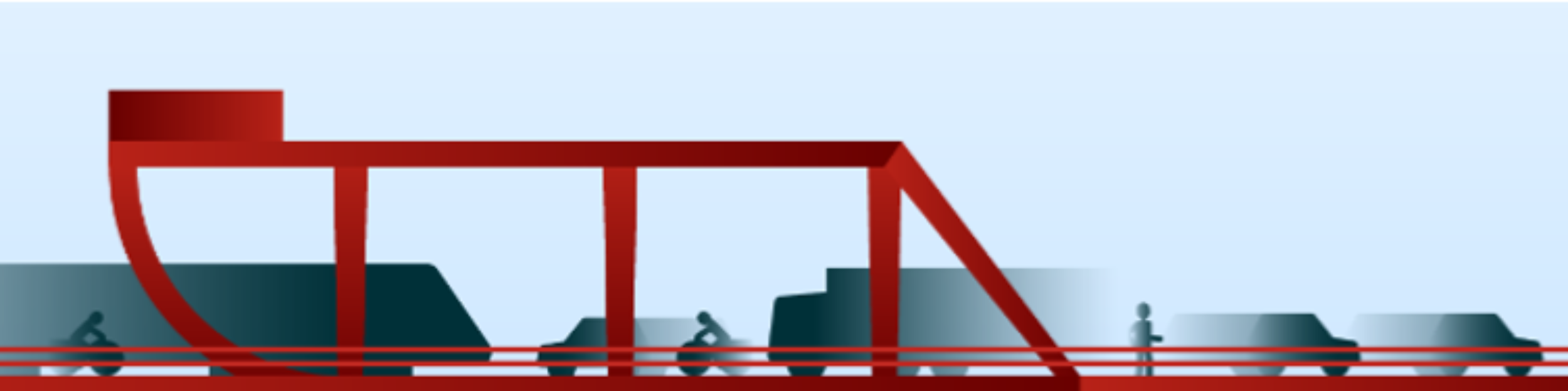

Autonomous trains reduce the need of humans in the entire process of running a train. However trains cannot go from zero level to the highest level of automation without going through various levels in between. There are different levels for automation(GoA) as mentioned below:

- GoA0 Manual driving. Here no systems such as Automatic Train Protection (ATP) are being used and the train operator is fully in control of all safety and efficiency of the train movements. Visual and audio signals and regulation from the environment are used to authorize the movement of the train.

- GoA1 Manual driving with ATP. The train operator is responsible for the ac- and deceleration of the train, the control of the doors and the monitoring of the track conditions.

- GoA2 Semi-automatic train operation (ATO) with full ATP. The train operator is still behind the controls, but now only controls the doors and departure and monitoring of the track.

- GoA3 Driverless train operation (DTO) with full ATO and full ATP. The train operator is not constantly needed behind the controls and can also function as an attendant. Interference of the train operator is only needed in emergencies.

- GoA4 Unattended train operation (UTO). There is no train operator needed, only attendants to serve the passengers.

Report Summary:

- In the report, a desired level of automation existing in Netherlands(GoA 2) is selected and based on this, subsystems are defined for the train. Next the different stakeholders involved, humans and environment is mentioned. A safety cube is used to find their interaction for safe integration and another safety cube with a focus on the system is created. The function of the system and its functions across time is also mentioned.

- Accidents which are caused due to automation in railways are collected to come up with safety measures later on.

- Afterwards, safety levels are assigned for the different functions in the train(based on the sub-systems). Following this, safety regulations have been given for each of them.

- Next, hazards are identified and Preliminary Hazard Analysis is used to rank them on the basis of their severity and chances of occurrence. Risk Assessment Matrix is where the ranks are assigned along with various colors used to indicate the level of risk(high, moderate,low)

- Hazards of higher risk levels are selected and control measures are assigned for them. For less severe risks, cost benefit analysis is carried out to determine if controls are required or not.

- In the end, the system is monitored using the safety indicators and safety culture is discussed about.

The report is given along with the presentation below.