The investigation of the cause of malfunction in the system and how to improve it.

Maintenance and fault finding

S. Coates, “CAA International (CAAi),” CAA International (CAAi), Dec. 03, 2021. https://caainternational.com/security-culture-human-performance/ (accessed Mar. 15, 2023).

In order to have unintended disruption to the service, the quality of the service must be maintained

at a certain frequency. This is where maintenance becomes important, most aircraft and high-speed

vehicles have been suffering from unintended and uncontrolled collisions with each other [7]. A system

could be made to monitor those vehicles and control their position to avoid any hazardous collision.

The implementation therefore of a control centre monitoring the magnets intensity distribution along

the rail, the pressure-vacuum force levels as well as the precise coordinates but also the direction of

each pod displacement would be ideal. Another major concern that could be resolved would be the

use of a backup system if the primary one fails. The use of an internal safety vehicle could also be

of use to act as a lifeboat and quick response service for in case of an anomaly happening to the pod

carrying the passengers and act as a safe evacuation boat. That would require trained first responders

available 24/7 to be familiar with the pod and how to access it in many different ways. However,

that would place the responders, as well as the malfunctioned pod at risk as the tunnel could be used

by other pods travelling and approaching the accident at high speed therefore disabling the partial

sections of the tube for the assistance workers would be the safest response.

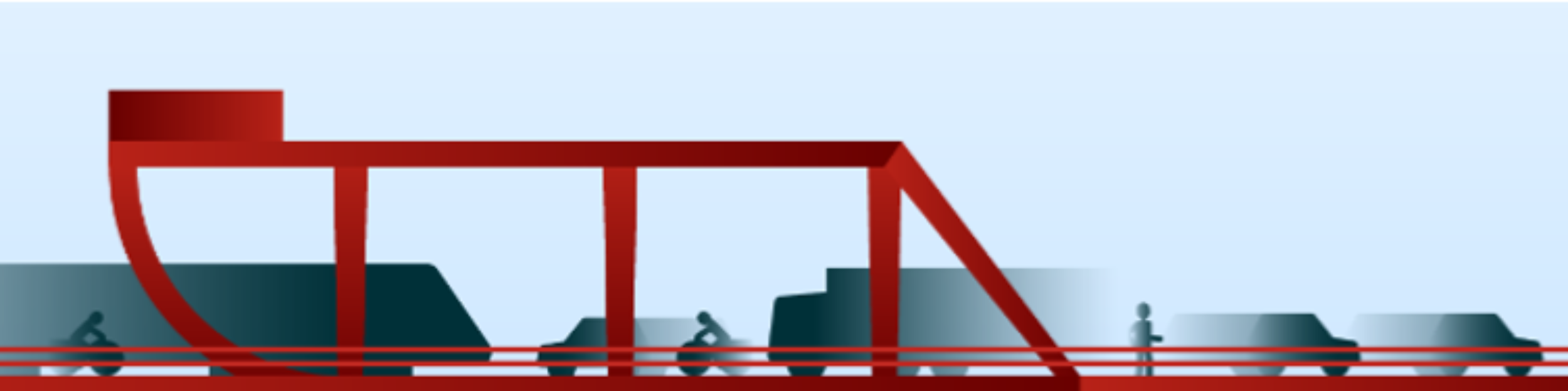

The hyper loop system has been designed, to obtain an optimal lifetime expectancy, the maintenance of this system for each component is analysed and defined in figure 2.

The system is composed of a Pod, the tunnel, and the station. Stations have been designed for

over a century with trains therefore this subsystem is already existing and its maintenance is known.

Refurbishments over time will be essential to update its electronic sensors such as for tracking the

Pods and the user interface between the passengers and the vehicles such as for guiding them to the

correct platform to making sure they have a valid ticket once boarded the pod.

The pressure level inside the tunnel system will be close to vacuum but still there will be some

air inside, as time proceeds, more air is being added to the tunnel, after a specific amount of oxygen

level the air drag will become significant to the pod which will require more power to overcome this

friction drag therefore making the system inefficient. It is important to save energy to make the system efficient, therefore maintenance in sealing the sectioned tube with an extra coating will be added

in the connecting tube edges area where air is expected to be leaking. The tunnel will be pressure

monitored with multiple sensors withing each tube section.

For the electromagnets, when the pod travels, vibrations will be gradually caused by the inconsistency of magnetic power to levitate the pod therefore after a certain range of vibrations the levitation

electromagnetic coils will require maintenance. In addition, the latitude electromagnets which serve

to keep a horizontal distance from the track will start to deviate the distance by time and a calibration

of the sensors calculating the distance will be required. The magnets experience a decay of magnitude

in function with time therefore after several maintenance sessions have been performed in re aligning

properly the magnets and cleaning up from dust and replacing the induction coils, the magnets will

eventually require to be replaced when too much vibrations are happening to the pod which is a

condition based maintenance in combination with preventive as parts will be replaced. The magnets

on the track are much more expensive and greater in terms of amount compared to the pod’s magnet

therefore to keep a consistent track levitation, all the magnets will be replaced after a specific amount

of cycles made by the pods.

Root cause analysis

As the pod is the primary asset of the system from the fact that it carries human lives on board, a

root cause analysis of that subsystem will be determined around the pod. The pod could be damaged

in several ways and therefore to analyse how and in which situation it could be damaged or destroyed,

a root cause analysis has been performed. This analysis is shown in figure 3.

The root cause analysis indicates the way how the pod could be damaged which the main reasons are from derailment, collision and depressurisation. It has been a fact that dutch trains tend

to derail when they do not obey speed limits for a specific track [1] or collide with obstacles. In

the case of the magnetic system, the pod needs to levitate as well, loosing the levitation power the

train will derail but that is very unlikely as already existing technologies using the levitation system

(Maglev) [2] makes that the further the vehicle gets from its track, the stronger the magnetic force

pushing it back However possible debris or electrical supply may insist in the derailment. Therefore it

is important for the magnets to be maintained regularly and when required to avoid any malfunctions.

In addition, the pod could collide with other pods which have lost contact with the station control,

therefore it is important to not only relay telemetry from the pod to the command centre but also that

the command centre surveilles the pod independently with the use of surveillance cameras. Lastly, the

analysis shows that the pod could have cabin depressurisation either from a leaking hole caused by a

debris collision, or from sensors failure and opening the door this is why a hyper loop crew should be

onboard, to offer the possibility to close the door hatch manually if required.

Safety risk monitoring and control

Monitoring safety risks should be performed by identifying, assessing, evaluating, removing, and controlling the issue to overcome the circumstances where the risk poses a threat to human lives. To

control and repair the risks, the hyperloop system should be composed of a centralised safety department per station. That department should be responsible for making sure that the pods would

function within the safe margins and not function with broken parts needing replacement. The control

department will monitor the hyper loop and its subsystems constantly and possible risks should be

identified before hazards occur. Table 6 analyses how the hyper loop could be monitored by making

quantifiable indicators of progress toward the intended performance goal also called Key performance

Indicator where also their measurement methodology is explained.

To measure the safety of the hyper loop system and therefore to ensure that the system fulfils the

mission for which it was designed, the pod is constantly monitored, the maintenance will also take

place in parallel with the check ups performed by sensors and personnel with reading various data

which should be within acceptable limits to operate with the safety regulations. It is very important

to be a reliable transportation mean for humans. Therefore it is expected to satisfy the passengers

and all workers involved in it by lowering the amount of delay, maintenance time, incident and most

importantly reducing the fatalities caused by other means of transportation. The Key performance

indicators are not only about reliability but also about safety. Therefore a performance indication

of the hyper loop would be the amount of failures per subsystem. Such as the derailment or the

frequency that the pod goes to over-speed or the other way around. Monitoring those situations will

help to further reduce the failures and dangerous problems that may arise during travel to make the

system more safe to use for the passengers.

References:

[1] NS. Disruptions on the rails. 2023.

[2] The guardian. Maglev trains: why aren’t we gliding home on hovering carriages? 2023.

[3] NASA. Simulation of space junk collision: When a 1/2oz ( 14g) piece of plastics traveling at

15,000mph ( 24,000kmph) hits a block of aluminum. 2023.

[4] Jeffrey Kenworthy Smriti Premsagar. A critical review of hyperloop (ultra-high speed rail) technology: Urban and transport planning, technical, environmental, economic, and human considerations. 2022.

[5] Railtech.com. Elon musk confirms the boring company will construct hyperloop. 2022.

[6] Wikipedia. Sky marshal. 2023.

[7] Moises Tvtv. Mayday why planes crash collision course air crash investigation. pages –, 2017.

[8] Jake hardiman Mark finley. Where are an aircraft’s safest seats? 2022.

[9] Teruaki Hasegawa Akihiro Kagamihata Yuichiro Kida Takamitsu Seike Takahiro Watanabe Toru

Hara Toshiro Itoga Yoshihiro Asano Takashi Tanaka Teruhiko Bizen, Ryota Kinjo. Radiationinduced magnetization reversal causing a large flux loss in undulator permanent magnets. Scientific reports, 6:1–9, 2016.

[10] BBC journal. Crossrail: Who wants to work in a tunnel? 2015.

[11] David M. Harland. Constellation program. 2009.

[12] Wikipedia. Space launch system. 2023.

[13] Asimina Voskaki. Coping with ‘extremes’ – keep calm and fly. . . . 2020.

[14] National Geographic. Mar 11, 2011 ce: Tohoku earthquake and tsunami. 2011.

[15] Patrick Kingsland. Will maglev ever become mainstream? 2018.

[16] Jasmine Reimer. More than people, hyperloops can transport shipping containers and reduce

co2. 2022.

[17] treinreiswinkel. Trein utrecht centraal – schiphol (airport) — alle treintickets. 2023.

[18] Wikipedia. Concorde. 2023.

[19] NASA. Ames’ contributions to the x-59 quiet supersonic technology aircraft. 2022.

[20] NASA. Introducing symphony, the boom-developed engine for overture. 2023.

[21] S.K. Das and J.G. Kaufman. Recycling aluminum aerospace alloys. 166:1161–1165, 01 2007.

[22] David Jones. What are industrial lifting magnets and where are they used in businesses? 2021.

[23] Akiva Blander. When a building comes down, where do its materials go? 2019.

[24] Railsystem.net. Maglev. 2023.

[25] Jose M. Mateu, Pablo Mart´ınez Fern´andez, and Ricardo Insa Franco. Setting safety foundations

in the hyperloop: A first approach to preliminary hazard analysis and safety assurance system.

Safety Science, 142:105366, 2021.