Introduction

Wind turbines are a very interesting topic in a safety point of view.

Wind energy is a source of renewable energy. It is inexhaustible and reduces the use of fossil fuels, which are the origin of greenhouse gasses that cause global warming [1]. Therefore is not a surprise to see that the number of wind turbines operating in the last years as increased. It is expected that this growth continues in the next few years [2]. With an increase in the number of wind turbines installed, the number of accidents as increased as well as we can see in the image below [3]:

One of this accidents occurred in Hornslet, Denmark. The wind turbine in which the accident occurred was a Vestas wind turbine (Nordtank NKT 600-180/43) with a maximum generation capacity of 600 kW [4].

The wind turbine entered service on December 23, 1996, as the first in a row of five wind turbines.

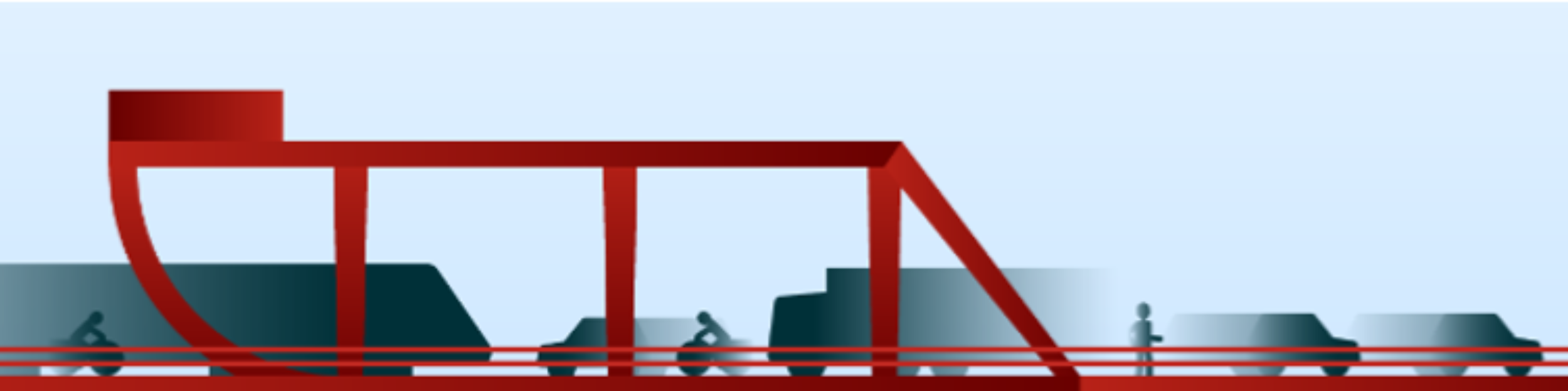

There are mainly two types of wind turbines: onshore and offshore wind turbines. This was, as we can see in the image below, an onshore wind turbine [5] .

The accident occurred on the 22th of February of 2008.

Following the catastrophic failure of the asset, the Danish energy agency requested an investigation into the events. A report was produced by engineers at Risø DTU. The chain of events listed below, was taken from that report [6].

Chain of events

- Service was requested for the turbine, following a malfunction of the brakes (cause: worn brake). At the last routine major check-up, it was noticed that the main gear made some noise. It was then recommended to have an endoscopic inspection done.

- A service team from Vestas arrived Friday morning (22 of February) to check the brakes. The brakes were repaired and checked.

- The braking mechanism is tested eight to ten times from the nacelle. Then the turbine is restarted from the bottom of the tower, with the intent of putting it back into normal production. At this point, the wind is very strong. The airbrakes at the tip of the blades are used to control the speed of the rotor, prior to attaining operational speed, according to Vestas. That means the tips of the blades are turned out during the start.

- During the start of the turbine, just when it is put back on the grid, noise is heard from the nacelle. The service personnel press the stop button. The turbine’s control system starts a controlled shutdown procedure, but a large crash is then heard (probably the gear that fails). The turbine is shaking strongly and cable assemblies, etc., fall down inside the tower. The rotor stops abruptly for a moment, but then starts turning again. The speed of the rotor is rather low, but it is noted that the turbine no longer can be controlled from the control panel and stopped by the brake on the high-speed axle. The personnel evacuates the tower immediately. Outside, it is observed that the airbrakes at the tip of the blades have broken off.

- The turbine continues to gain speed, and attains speed beyond its design limit

- The service personnel contacts the local police and assist in establishing a safety zone of 400 meters and warn the neighbours. This continued for 21/2 hours.

- The turbine wrecks. The result is that the blades collapse, the tower is hit and is strongly indented. The nacelle is bent forwards (against wind direction). Pieces of all three blades are thrown a great distance downwind from the tower, almost 180 degrees.

- The nacelle and the upper part of the tower falls to the ground in front of the tower. The generator falls out and rests next to it.

- Large pieces of the blades land 200–300 meters away, while small pieces appear to have flown 500 meters.

During this chain of events nobody was hurt. Local reports said that the braking system failed while 2 technicians worked in the turret in the top. They got out before the collapse [7].

As mentioned previously, the wind turbine failure is recorded on video. The video is avaiable in streaming platforms (e.g. YouTube).

The image below, contains 3 frames, from the mentioned video. The 3 frames allow to have a better perspective of the evolution of the systems failure and degradation.

Conclusion

As a consequence of this accident there was a need for better evaluation of brake systems (soft brake and smart brake systems). Another consequence was the loss of reputation and faith on wind turbines. Denmark generated 20% of its own energy from wind turbines back in 2009 and Vestas specifically occupied almost 20% of the global market in 2008 [8]. The accident made people afraid of wind turbines, since debris were found at long distances from the wind turbine, representing a major safety hazard for people passing by or people living near such systems.

As a result of this accident, better wind turbine breaking systems were designed, to avoid this type of situations.

This accident could have been avoided through a better desing of the brake system.

The airbrake has the function of stopping the blades rotating if the wind intensity is too high. As mentioned previously, the airbrake of this wind turbine broke off. If this did not occur, it was very likely that the wind turbine’s blades would not have reached such an high speed.

Therefore by designing a backup system, which took into account this hazard (airbrake broken), and that in such a situation, would be responsible for controlling the blades’s speed, the wind turbine could have been stopped or the blades speed reduced to a safe speed.

References

[1] P. Musgrove, Wind Power, Cambridge University Press, 2019.

[2] Mordor Intelligence, “Wind Power Market- Growth, Trends, and Forecast (2019 – 2024),” 2019. [Online]. Available: https://www.mordorintelligence.com/industry-reports/global-wind-power-market.

[3] Caithness Windfarm Information Forum , “Summary of Wind Turbine Accident data to 30 September 2019,” 2019. [Online]. Available:

http://www.caithnesswindfarms.co.uk/AccidentStatistics.htm.

[4] Wikipedia, “Hornslet wind-turbine collapse,” [Online]. Available: https://en.wikipedia.org/wiki/Hornslet_wind-turbine_collapse.

[5] Google Maps.

[6] Risø DTU, “Final report on investigation of a catastrophic turbine failures, February 22 and 23, 2008,” 2008.

[7] Caithness Windfarm Information Forum, “Detailed Accident List,” 2019. [Online]. Available: http://www.caithnesswindfarms.co.uk/fullaccidents.pdf.

[8] Vestas, “Annual report 2008,” 2008.

Additional References used:

https://www.statista.com/statistics/991055/share-of-wind-energy-coverage-in-denmark/