In 1999 three workers received high doses of radiation in a small Japanese plant preparing fuel for an experimental reactor. The cause of accident was the bringing together of too much uranium enriched to a relatively high level, causing a ‘criticality’ (a limited uncontrolled nuclear chain reaction), which continued intermittently for 20 hours. A total of 119 people received a radiation dose over 1 mSv from the accident. Fortunately, only three operators’ doses were above permissible limits while two of the doses proved fatal. The cause of the accident according to the International Atomic Energy Agency (IAEA) was “human error and serious breaches of safety principles”.

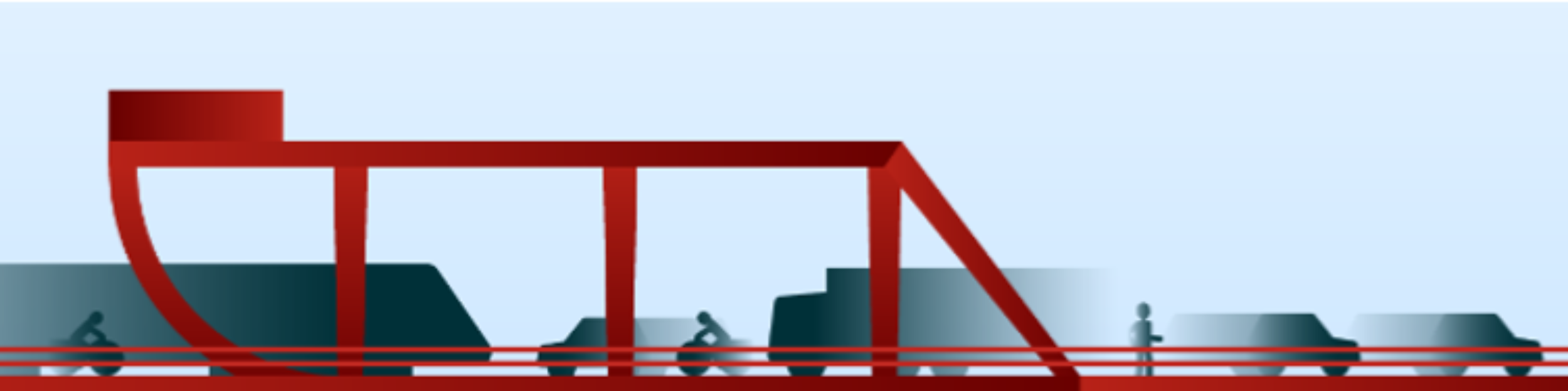

The Tokai-mura accident was in a very small fuel preparation plant operated by Japan Nuclear Fuel Conversion Co. (JCO), a subsidiary of Sumitomo Metal Mining Co. It was neither part of the electricity production fuel cycle, nor was it a routine manufacturing operation where operators might be assumed to know their jobs reasonably well. The JCO plant at Tokai was commissioned in 1988 and handled up to 3 tonnes per year of uranium enriched up to 20% U-235, a much higher than for ordinary power reactors. The plant provided various dedicated research and experimental reactors. It uses a wet process. The permitted nuclear fuel preparation procedure involved dissolving uranium oxide (U3O8) powder in nitric acid in a dissolution tank, then its transmission as pure uranyl nitrate solution to a storage column for mixing, followed by transfer to a precipitation tank. This tank is enclosed by a water-cooling jacket to remove excess heat generated by the exothermic chemical reaction. The inhibition of criticality was based upon the general licensing requirements for mass and volume limitation, as well as upon the design of the process. A key part of the design was the storage column with a criticality-safe geometry and allowing careful control of the amount of material transferred to the precipitation tank. However, the company’s work procedure was improved three years earlier, without authorisation from the regulatory authorities, to allow uranium oxide to be dissolved in stainless steel buckets rather than the dissolution tank. It was then modified further by the operators to speed things up by tipping the solution directly into the precipitation tank. The mixing intended to occur in the storage column was instead undertaken by mechanical stirring in the precipitation tank, thus side-stepping the criticality controls. Also, there was no proper control of the amount tipped into the hundred-liter precipitation tank, and its shape (450 mm diameter and 660 mm high) improved the likelihood of criticality within it.

On 30 September three workers were making a small batch of fuel for the experimental fast breeder reactor, using uranium enriched to 18.8% U-235. It was JCO’s first batch of fuel for that reactor in three years, and no proper qualification and training requirements had been established to prepare those workers for the job. They had earlier used this technique many times with much lower-enriched uranium – less than 5% and had no understanding of the criticality consequences of 18.8% enrichment. At around 10:35, when the volume of solution in the precipitation tank reached about 40 litres, containing about 16 kg U, a critical mass was reached. At the point of criticality, the nuclear fission chain reaction became self-sustaining and began to emit intense gamma and neutron radiation, triggering alarms. There was no explosion, though fission products were increasingly released inside the building. The significance of it being a wet process was that the water in the solution provided neutron moderation, expediting the reaction. (Most fuel preparation plants use dry processes.) The criticality continued intermittently for about 20 hours. It seems that as the solution boiled vigorously, voids formed and criticality ceased, but as it cooled and voids disappeared, the reaction resumed. The reaction was stopped when cooling water surrounding the precipitation tank was drained away, since this water provided a neutron reflector. Boric acid solution (neutron absorber) was finally added to the tank to ensure that the contents remained subcritical. These operations exposed 27 workers to some radioactivity.

The three workers concerned were hospitalised, two in a serious condition. One died 12 weeks later, another 7 months later. The three had deceptively received full-body radiation doses of 16-20,000, 6-10,000 and 1-5000 millisieverts (about 8000 mSv is normally a fatal dose), mainly from neutrons. Another 24 JCO workers received up to 48 mSv. Doses for 436 people were evaluated, 140 based on measurement and 296 on estimated values. None exceeded 50 mSv (the maximum allowable annual dose), though 56 plant workers exposed accidentally ranged up to 23 mSv and a further 21 workers received elevated doses when draining the precipitation tank.

According to the IAEA, the accident “seems to have resulted primarily from human error and serious breaches of safety principles, which together led to a criticality event”. The company conceded that it violated both normal safety standards and legal requirements, and criminal charges were laid. The fact that the plant is a boutique operation outside the mainstream nuclear fuel cycle evidently reduced the level of scrutiny it attracted. The state regulator had visited the plant only twice per year, and never when it was operating.

Mainstream fuel fabrication plants in Japan are fully automated, engineered to ensure that criticality does not occur, equipped with neutron monitoring systems and fully prepared for any possible criticality accident. Most plants use a dry process in any case, which is intrinsically safer. No major civil reactor uses uranium enriched beyond 5% U-235.