On the 12th August 1985 at 24,000ft 18:24 local time, the Japan Airlines Flight 123 (JA8119) domestic flight from Tokyo international airport to Osaka International Airport suffered mechanical failures 12 minutes into the flight and 32 minutes later crashed into two ridges of mount Takamagahara in Ueno, Gumma Prefecture. On board the aircraft carried 524 person in total including the crew and 12 infants , of which 520 were killed and 4 passengers got injured seriously.

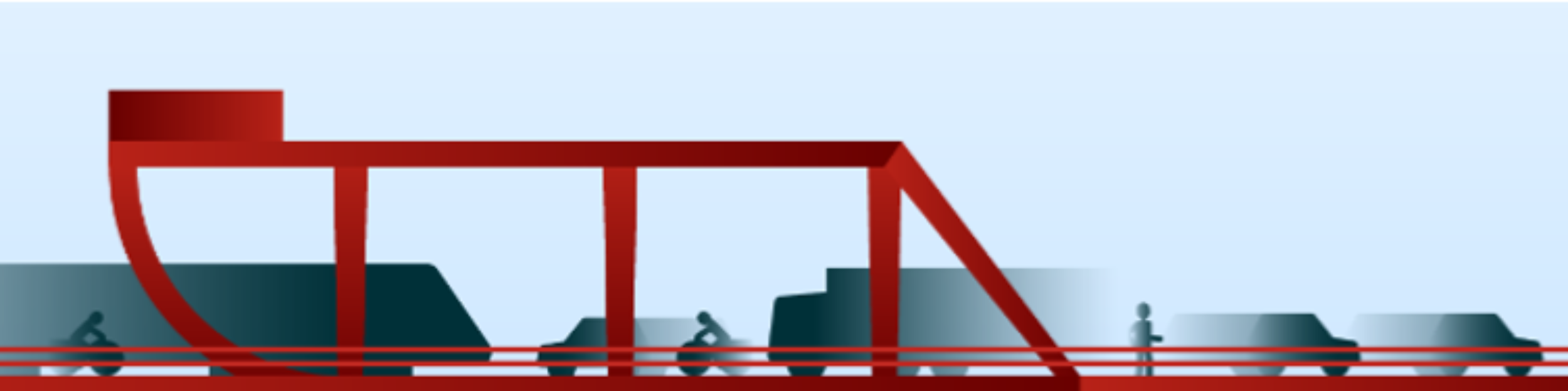

The accident was caused by decline of flying quality and loss of primary flight control function due to rupture of the aft bulkhead causing the bulkhead to blow out, creating overpressure in the tail sever in the four sets of hydraulic control lines and blowing part of the tail section off. After continuous investigation into the accident it was found that it was the improper maintenance 7 years ago that caused the failure of bulkhead. The japan aircraft experienced a tail strike on the runway during a landing at Itami airport seven years prior to the accident. The repair was made using two separate splice plates instead of a single plate. As a result the entire load transmitted through the centre rivet only resulting in formation a many small fatigue cracks originating from the joint, which increased gradually over the seven years.

Acciddents such as this are caused solely by human error. Its difficult to remove the human factor out of the system unless if the system is to be rigid and inflexible. The maintenance operations and inspections task are a complex part of the aviation industry. Inspections should be carried out at appropriate intervals after large repairs and design changes so that to check that the designers intention is completely satisfied and are carried in proper order. Fundamental training in all the areas relating to the aircraft should be provided in detail even to the engineers at the site. Supplying operator with tools to perform experiments and test hypotheses to make limits of acceptable performance visible while still reversible to tolerate the human error.

references

- https://www.youtube.com/watch?v=lqvav-vKZkI

- https://www.thevintagenews.com/2018/01/06/japan-airlines-flight-123/

- https://www.tailstrike.com/120885.htm