In June of 1998, one of Germany’s InterCity Express (ICE) trains, travelling at over 200kph, slammed into an overpass, killing 101 people. The accident happened to a high-speed ICE train just outside the town of Enschede. It remains the worst rail disaster in the history of the Federal Republic of Germany and the worst high-speed-rail disaster worldwide.

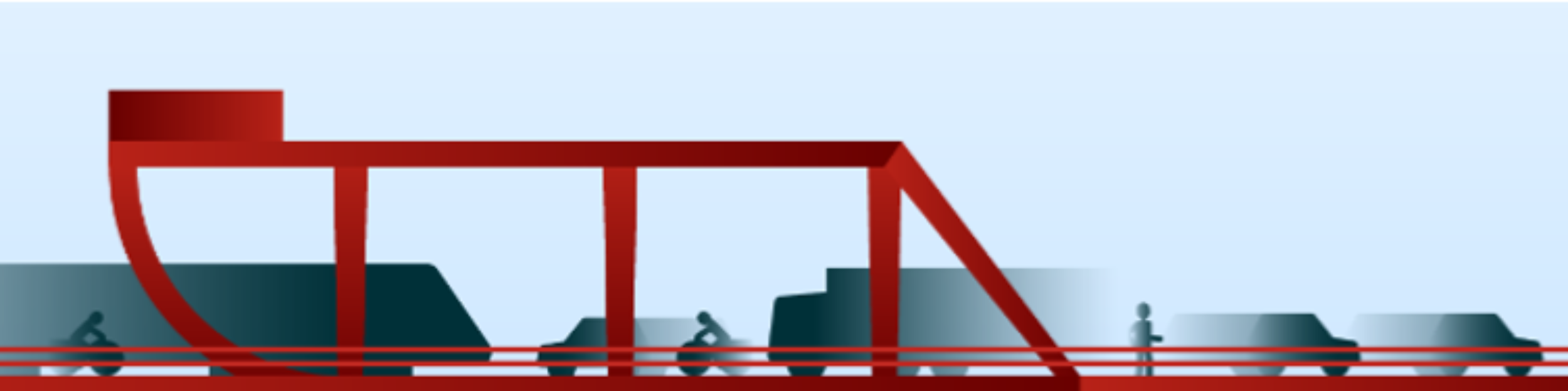

The train ICE 884 with 12 carriages and 2 locomotives on the route Munich–Hamburg, when near the village Enschede the tire of a rubber-sprung wheel, broke at a speed of above 200 km/h. The tire detached from the wheel was dragged along, jammed under the floor of the carriage and then got stuck in the tongue of a switch. By this, the switch was toggled to the neighbouring track and the hind part of the train redirected there. The collapsing bridge buried a part of the train. The train travelled over 3 km before derailing. Cars were crushed when an overpass, which was not designed to withstand the impact of train derailment, collapsed. The force of the collision, combined with the speed of the train’s rear engine, propelled the rear wagons into the structure. This led to derailment and collision of the derailed train part with the pylon of a road bridge leading over the tracks. The consequences of this catastrophe were beside with enormous material damage and interruption of train service 100 dead and more than 100 injured passengers.

A cracking inside the ring of the wheel was responsible. There was no indication of material or production failure. This crack was caused by excessive load and wear. When ICE commenced operations, there was no certification in place that would document fitting design and reliability. Furthermore, no fracture mechanic calculation was done that could prove the strength of the wheel during its lifetime. According to the experts, such wheels should not be operated at less than 880 mm diameter (new condition = 920 mm), subject to annual testing for inner and middle zone cracks. The diameter of the accident wheel was 862 mm. The limit set by Deutsche Bahn is 854 mm.

On the approximately 100 wheels, which had been taken out of service before the accident, no cracks or flaws have been reported when they were disassembled and scrapped while on the remaining 5000 wheels (approximately) removed after the accident several cracks were found in tires but no fractures. It could be seen that the cracks had occurred in wheels with larger diameters than that of the accident and without pre-existing flaws. This gives support to the presumption of a rare or singular event which could have initiated the crack. It also supports the assumption of a mostly quite low mean loading level because these cracks had grown up only very gradually or not at all and never reached a critical depth. (which were detected later).

Prior to the commissioning of the wheel, there were performed strain measurements on a prototype of the wheel, fatigue tests on complete wheels and extended service tests on rail tracks. This procedure corresponded to the UIC-recommendations (Worldwide Railway Organization) in force at that time. Seen from the present day’s viewpoint, facilities for design would be better. For this type of rubber-sprung wheel, no individual or particular UIC-guideline existed. Nevertheless, the recommendations for monobloc wheels could correspondingly also be applied here.

The case has revealed as areas for improvement that upgrading of design rules or international standards is essential, that realistic measurement of service loads and impact factors should be carried out before design work, that the weak spots need to be identified by tests on roller type test stands until fracture and non-destructive test of these weak spots ought to be done in the regular service checks.