Starting 25 January, Asab GASCO plant shutdown was planned. Until 11 Feb. 2009. 2009. This resulted in a complete shutdown of ADCO production. The shutdown provided opportunities for key maintenance activities in the Asab, Sahil and Shah areas. In Shah, the key maintenance activities planned included partial replacement of the transfer line and removal of twoKM-58and KM-68 stuck corrosion coupons recovery tools. At KM-68, the removal of the stuck corrosion bond recovery tool was performed successfully with approx. drainage. 200 crude barrels from the transfer line. The removal of the stuck corrosion bond recovery tool at KM-58 required drainage of approximately. 1600 crude barrels from the transfer line.

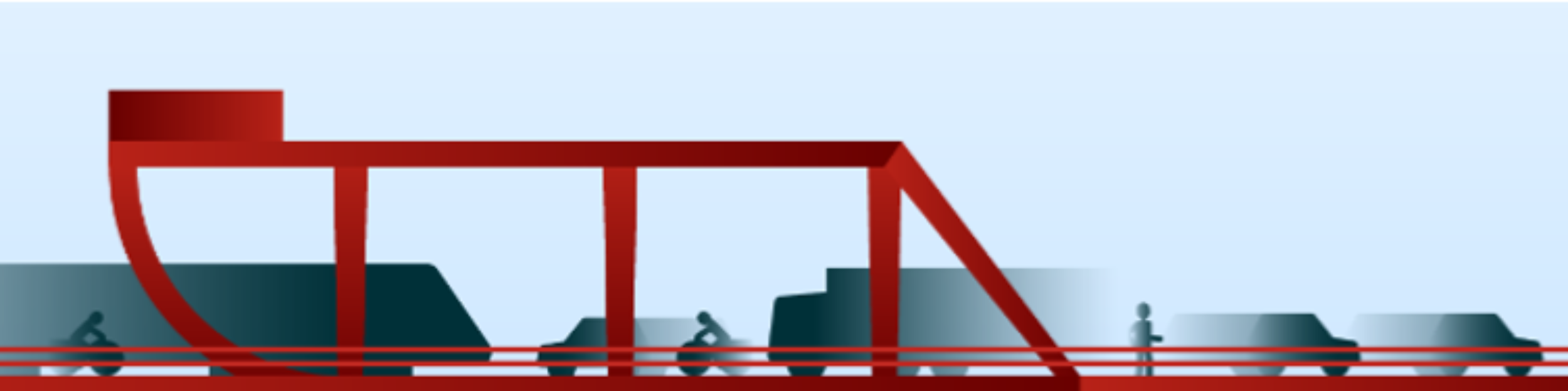

Events of the tragic day A forester and five workers worked with the drainage of a transfer line into a corrosion cupon pit (confined space) (without obtaining a work permit) exposed to H2S gas (colorless and odorless gas). He fell back when he tried to get out of the pit and hung upside down and his leg trapped inside the ladder. Foreman entered the pit to rescue the worker and asked a second worker to close the valve and rescue him. The second worker entered and began to help, but the foreman collapsed and soon after the second worker collapsed, a head injury was sustained by hitting an object (he survived). The third worker entered the pit to rescue his colleagues and collapsed. The two workers outside the pit were seeking assistance from the Shah control room.

Controls measure that should be implemented are as follows:

- Ensure that PTW (permit to work) is issued on the basis of a Task Risk Assessment (TRA) and a safety professional (Safety & Loss Prevention Engineer (SLPE) has approved the TRA as a minimum).

- Confined space entries can not be made unless a SLPE is present and the emergency plan has been reviewed.

- Empower workers to undertake unsafe activities and enter into contractual arrangements to protect / encourage persons who practice ADCO STOP policy.

- Provide personal H2S detectors for all staff including workers in exposed areas of H2S. Ensure that all employees and helpers are fully trained to carry out their tasks.

- Include practical elements (step testing) and confined space in H2S / BA training and for all operation / production and HSE personnel.

- Establish access control on all confined areas with effective markings, signs and tagging and, where applicable, locking.